Shell Nigeria Exploration and Production Company (SNEPCo) has said it achieved significant savings in the cost of subsea equipment through an initiative which has seen the refurbishment of five Subsea Trees in-country led by Nigerian engineers.

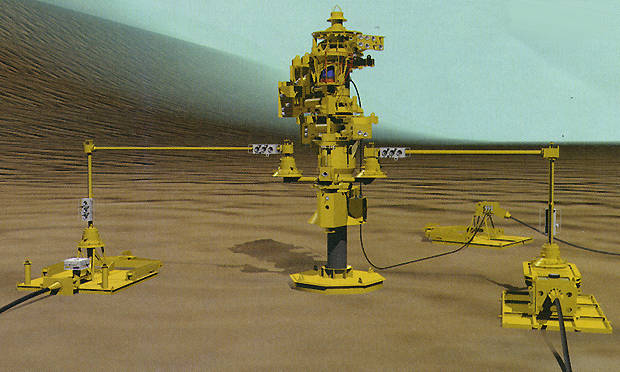

A Subsea Tree is an arrangement of valves and other components installed at the wellhead to control and monitor production/injection flow. SNEPCo embarked on a Tree Refurbishment initiative in 2013 to ensure timely delivery of the equipment at lower cost for the Bonga Phase 2 project, which comprises drilling and hook-up of in-field wells within Bonga.

“Beyond cost consideration, we were also looking to indigenise the know-how so that Nigerian engineers can acquire the necessary skills,” said Mr. Bayo Ojulari, Managing Director of SNEPCo. “We are pleased with this success story. The first Subsea Tree under the programme was installed on schedule in May 2015. This was the first of its kind re-using a Subsea Tree fully stripped down and refurbished locally in Nigeria, with all of its original functionality restored.”

According to the organisation, it saves about $6 million for every refurbished Subsea Tree, which is delivered within 15 months as against 36 months for newly manufactured ones.

SNEPCo’s Engineering Manager, Subsea and Pipelines, Mr. ‘Debo Oladunjoye, who leads the refurbishment team, said: “The scope of work entails the retrieval of Subsea Trees for disassembly, repair and rebuild following procedures developed by the Original Equipment Manufacturer (OEM) to international standards and codes. The work is done at the OEM/SNEPCo logistics base at Onne in Rivers State with Nigerian engineers and technicians playing key roles. The expenditure on this work in Nigeria aligns with the cost of similar Subsea Tree refurbishment in Europe. We are currently refurbishing three Subsea Trees.”

SNEPCo disclosed that it helped to create the first generation of Nigerian deep water professionals through the Bonga project which started production in 2005, as Nigeria’s first deep water oil and gas production project in more than 1,000 metres of water. To sustain production and keep the Bonga Floating Production Storage Offloading (FPSO) vessel full, additional in-field wells have been delivered as part of the Bonga Phases 2, 3 and Bonga North West projects, all producing through the Bonga FPSO.

SNEPCo operates Bonga field on behalf of the Nigerian National Petroleum Corporation in partnership with Esso Exploration and Production (Deepwater Ltd) (Exxon), Total E&P Nigeria Ltd (Total) and Nigerian Agip Exploration Ltd (ENI).

So, Nigerian Engineers are cheap.It’s good to know.